Karl Benz registered his first car in July 1886, the three-wheeled Benz Patent Motor Car, model no. 1. That single cylinder four-stroke engine produced three-quarters of a horsepower and included an automatic intake slide, a controlled exhaust valve, and evaporation cooling.

Various engine refinements were made in the intervening century, but it wasn’t until recent years that new technologies began to make a big difference.

Today’s internal combustion engines are smaller, lighter and more powerful than engines built a generation ago, delivering improved fuel economy and emitting fewer emissions thanks to several important technologies common today.

Fuel Injection

Drivers who grew up with cars outfitted with a carburetor can certainly appreciate that fuel injectors took over by the early 1990s. The lowly carburetor was inclined to flood the engine, cause hesitation or contribute to fast idling.

With fuel injection, fuel is atomized by forcibly pumping it through a highly pressurized, small nozzle. The air/fuel mixture is precise, minimizes waste and is cost effective. Give credit to fuel injectors for improving fuel economy, enhancing engine performance and for reducing emissions.

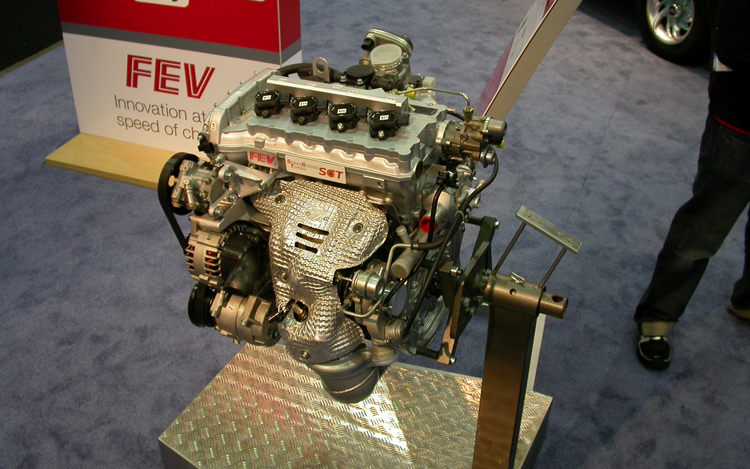

Aluminum Engines

Iron block engines are heavier and less efficient than aluminum block engines, the latter providing weight savings of up to 50 percent. Earlier aluminum engines, however, were prone to warping, but advancements in engineering have largely eliminated that risk.

Lighter engines are part of today’s product mix, what car manufacturers have been using to help lighten vehicle curb weights. Smaller aluminum engines coupled with other technologies mean that performance has been retained and fuel economy correspondingly improved.

Direct Injection

Where fuel injectors have replaced carburetors, direct injection systems are showing up as a replacement for earlier fuel injection systems. Also known as gasoline direct injection technology, fuel injectors are still widely used today.

Earlier fuel injection systems sprayed fuel into the intake manifold. With direct injection, fuel is sprayed directly into the engine chamber for a leaner mix of fuel. Direct injection burns more efficiently, reduces waste and is controlled by the engine’s computer to ensure precise delivery.

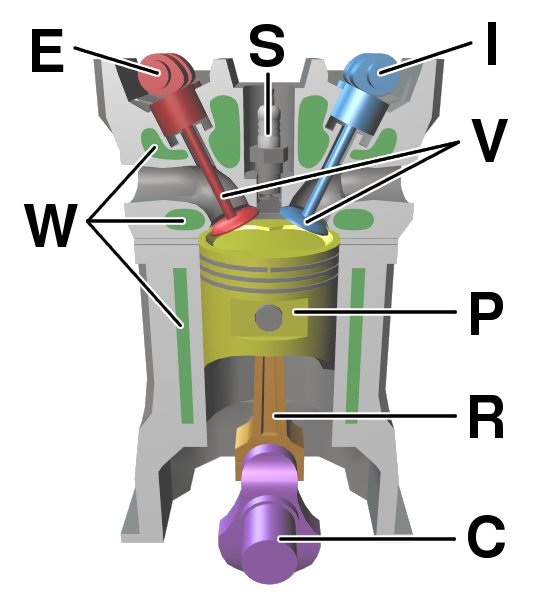

Variable Valve Timing

Multi-valve technology has given way to variable valve timing, the latter designed to enhance engine output. Valves are tasked with activating the breathing of the engine by timing air intake and exhaust.

Breathing is optimized by making it possible to vary the valve timing at different speeds and loads to correspond to varying work conditions. Those conditions are: low speed high load, high speed high load, partial load and lower temperature start and idling.

Overhead Cam Shafts

Overhead valve engines have given way to overhead cam shaft engines, although OHV is still used in some designs including Chrysler’s HEMI engines. With OHC engines, the camshaft is smaller and is placed above the cylinder head instead of in the engine block.

An OHC design permits additional intake and exhaust valves for an improved flow of air, fuel and exhaust.

OHC engines are marked as either SOHC for single overhead camshaft or DOHC for double overhead camshaft. As with other engine improvements OHC adds to the cost of delivering a more complex design.

See Also – Camshaft Position Sensor Replacement Cost

Computer Systems

So far as changes in engine construction, delivery systems and design have made today’s engines more efficient, perhaps the biggest gains would not have been realized apart from the advancements made with today’s in-car computer systems.

On-board diagnostic computers showed up in the 1980s and were improved and standardized beginning with OBD-II’s release in 1996. However, it is the engine control unit (ECU) that controls ignition timing as well as the air/fuel mixture, fuel delivery and idle to optimize performance.

Your vehicle’s performance, fuel economy and emissions output is largely dependent on the ECU. Yes, other computer chips are present too and are tasked with handling safety systems, navigation, the transmission and climate control.

Internal Combustion Engine Outlook

Despite the rise of vehicle electrification, including hybrids and pure electric vehicles, the outlook for the internal combustion engine remains bright. Today’s engines are much more complex and expensive, but the cost remains below that of emerging EV technologies.

See Also – Replace Your Timing Belt, Avoid Engine Damage

Karl Benz and internal combustion engine photo credits: Wikipedia.

- 2024 Mazda CX-50: A Compact SUV with Premium Aspirations - Apr 15, 2024

- 2024 Ford Mustang (Iconic Pony Car Evolves) - Apr 4, 2024

- 2024 Ford Maverick (Looks Like a Truck, Drives Like a Car) - Mar 28, 2024