The First “Check Engine” Lights

Some internet sources say the first car GM built with a “Check Engine” light the 1980 Cadillac Eldorado, but there are other sources that claim the Check Engine light showed up in the mid-1970s on vehicles with fuel injection.

But mid-model year 1980 brought GM’s electronic “feedback” carburetor with a control module that monitored an Oxygen Sensor in the exhaust. GM dubbed that early system “Computer Command Control.”

On those early GM vehicles, if you jumped two of the pins in the connector under the dash, the Check Engine light would flash out two-digit codes to point you in the general direction of whatever it was that caused those very basic computers to illuminate the CEL, which later became known as the “Malfunction Indicator Light.”

Then came scan tools and “serial data,” where GM provided the functionality of a scan tool that could not only read codes but display what the computer was doing with its inputs and outputs.

Ford and Chrysler were behind GM in adding the Check Engine Light and Scan tool diagnostics. Asian and Euro cars got the Check Engine Light and Scan Tool Data even later.

A New Federal Emissions Mandate

By 1996, all vehicles sold in the U.S. were required not only to have both, but to standardize trouble codes and component terms and to program the Powertrain Control Module (PCM) to include “Monitors,” which required new software and new hardware components.

This new federal mandate was referred to as “On Board Diagnostics 2” or OBD2.” Some one-ton trucks didn’t get OBD2 until 1997.

The new system required a Check Engine Light, a universal diagnostic datalink connector for the scan tool near the base of the steering column. It also required a Catalyst Monitor where an additional Oxygen Sensor was added behind the front “lightoff” catalyst(s) to monitor the catalyst’s oxygen storage capacity.

There was a Fuel System Monitor that kept track of Fuel Trim, an EGR Monitor, an Evaporative System Monitor and various other monitors, to include a Misfire Monitor.

The Misfire Monitor – Why?

While it might seem obvious to you that your vehicle is misfiring when it happens, you might be surprised just how hard it is to feel some misfires, and there are a lot of folks that don’t have a clue when their engine is misfiring. But the Misfire Monitor is in place to protect the catalytic converter.

The PCM counts misfires in 200 and 1000 revolution windows. What that means is that for every 200 revolutions of the engine, misfires are counted and stored, and if the number of misfires exceeds the acceptable number in the 200 window, a “Type A” misfire is flagged, which will trigger a flashing Check Engine Light.

A Type B misfire exceeds the acceptable misfire count in the 1000 revolution window and will illuminate the light but it won’t flash.

These misfire monitor thresholds are in place to prevent damage to the catalytic converter, because fuel that didn’t burn in the combustion chamber will most definitely do so in the catalyst. That overheats the converter, which, by the way, is covered under warranty for 80,000 miles or 8 years.

Aftermarket replacement converters are required to be warranted for 50,000 miles or 5 years due to sustained excessive temperature, which would be from 1600°F to 1800°F depending on catalyst design. Normal Catalyst temperature is generally around 1300°F.

How Does the Misfire Monitor Work?

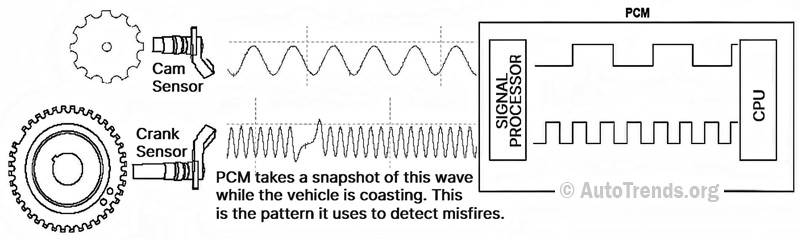

The illustration shown below is generic, and there are slight differences in the way Misfire Monitors work between platforms.

Some of the sensors produce digital signals (square wave) that don’t need to be processed by the PCMs CPU, and while cam sensor patterns differ (most only have three or four teeth on the trigger wheel), crank sensor patterns just about always have a 36 minus one crank wheel.

The Misfire Monitor uses both the cam and crank sensors together to determine which cylinder is misfiring. The cam sensor input is necessary because the crankshaft makes two full turns for each cylinder cycle. The cam sensor turns only one turn, which enables the PCM (or ECM) to pinpoint the misfiring cylinder(s).

This baseline “snapshot” the PCM stores has different names among manufacturers. Chrysler refers to this piece of stored information as the “Adaptive Numerator.” GM and Ford refer to it as “Crank Relearn” or “Case Relearn.”

One way or another, the PCM compares the live crankshaft pulses with the pattern it stored during the Crankshaft Learning process. But the PCM typically updates this information periodically on its own as a part of the “adaptive learning” process PCMs use.

The point of the “Crankshaft Learn” snapshot is that the PCM needs to know when the engine is misfiring, i.e., which cylinder isn’t contributing, and it can tell by watching the crankshaft slow down every time a particular cylinder doesn’t fire. It determines that by comparing the stored pattern with the live one.

Misfiring Triggers Other Things

Since the beginning of OBD2 Misfire Monitors, many platforms added an additional feature most people don’t know about.

To help prevent catalyst damage (which costs the manufacturer if it’s under warranty), the PCM is typically programmed to kill the injector on the misfiring cylinder very soon after a “dead” misfire is detected on that cylinder.

This can confuse a troubleshooter who isn’t familiar with this feature. If the injector is quiet and isn’t clicking on a misfiring cylinder, a less experienced mechanic might conclude that the silent injector is the reason for the misfire – the cause rather than a programmed effect.

Misfire Causes

Random idle misfires can be caused by spark plugs that are gapped too close or by partially fouled plugs.

Misfires under load can be caused by spark taking a different path than it is supposed to, meaning it’s not happening in the combustion chamber. This could be anything from a bad spark plug to a bad COP coil or Coil Pack to a faulty wire.

This can be caused by too long of an interval before replacing spark plugs, because spark is always looking for the easiest path and must be forced to find the right one.

Dead misfires can be due to internal mechanical engine issues, one or more bad spark plugs, a problem with the coil on that cylinder, spark plug wire issues, or problems with the circuit that triggers the coil on the misfiring cylinder.

When the Misfire Monitor has detected a misfiring cylinder, it will typically store a P030(x) code for that cylinder unless it can’t directly determine which cylinder is misfiring or if the misfire is moving from cylinder to cylinder (this does happen).

That triggers a P0300 code, which is annoying if you were hoping to get something more specific, like say, a P0304 or similar.

- Why Is My Check Engine Light Flashing? - Sep 25, 2023

A flashing Check Engine light means that your vehicle’s PCM detects misfires that exceed an acceptable number. But how serious is it?

Keep reading to learn how a Check Engine light works and what role the Misfire Monitor plays in determining which cylinder is misfiring.