Have you begun to notice an odd shaking or vibration coming from your vehicle when parked or stopped at a red light? If so, you’re not alone.

Issues of this type plague an untold number of vehicles on the road today and can arise from a host of potential underlying causes. In this article, we’ll work to demystify such occurrences, by answering the most common questions regarding a car shaking when idling.

See Also – Car Shakes When Accelerating? (Here’s Why)

Causes of a Car That Shakes When Stopped

Vibrations felt when stopped or at idle can be caused by one of several different causes, some of which tend to be more common than others.

Being familiar with these potential causes will allow you to be well equipped to diagnose and repair the issue at hand or know what to expect when taking your car in for service.

1. Inoperative Fuel Injector

A faulty or clogged fuel injector can certainly lead to a shake or vibration that is easily noticed at idle. This stems from the detectable misfire that such an issue presents.

Simply put, the cylinder in which the faulty injector is mounted is not combusting as it otherwise should, thereby leading to diminished contribution.

2. Faulty Plug, Plug Wire, or Coil Pack

Just as an inoperative fuel injector can cause a noticeable miss on a particular cylinder, so can a cylinder-specific spark-related issue.

Such issues often include damaged or mis-gapped spark plugs, faulty plug wires, or compromised coil packs. Misfires of this type are easily felt at low RPM.

3. Vacuum Leaks

Vacuum leaks tend to be an ever-present point of frustration for motorists the world over. Leaks of this type allow unmetered air into an engine’s intake tract, thereby skewing the resulting air/fuel ratio.

The affected engine then runs lean, causing noticeable performance issues, including unnatural vibration at idle.

4. Compromised Idle Air Control Valve

If your vehicle shakes or hesitates at idle, it might be due to a faulty or carbon-choked idle air control valve. This valve is responsible for metering the flow of air into an engine’s intake at idle when the throttle butterfly is closed.

If the idle air control valve fails or becomes carbon fouled an irregular or erratic idle often results.

5. Soiled or Clogged Air Filter

Another potential cause of shaking at idle is a heavily soiled or clogged engine air filter. This filter is responsible for screening incoming air, before its ultimate delivery to an engine’s intake manifold.

Restricted airflow at this point will cause an engine to run rich, thereby negatively impacting combustion efficiency as a whole. Replacing your consumable air filter or cleaning your reusable air filter is a quick fix.

6. Inaccurate O2 Sensor

Today’s vehicles come equipped with exhaust-mounted oxygen sensors, which interpret the state of an engine’s combustion gasses, by indicating a rich or lean condition. A vehicle’s PCM then makes adjustments to the affected engine’s fuel trims, in a bid to achieve greater combustion efficiency.

Inaccurate readings from one or more of an engine’s oxygen sensors often cause a harsh idle.

Is It Safe to Continue Driving?

In most cases, unless the shaking that you feel at idle grows significantly worse in a short period of time, continuing to drive a vehicle in such shape is generally considered safe, for at least the short term.

Typically, a misfire in only a single cylinder will not leave you stranded, nor will a minor vacuum leak. However, any issue of this type should be addressed before it is allowed to grow any more severe.

In any event, the root cause of a vehicle’s vibration at idle should be thoroughly diagnosed and repaired at the first available opportunity. Doing so will ensure that your vehicle’s engine is returned to peak operating efficiency, in the quickest way possible.

Why Does It Only Shake When Stopped and Smooths Out When Driving?

In most cases, a shaking that is felt at idle, but not at speed, is indicative of a single cylinder misfire. Essentially, a vehicle’s engine has a single cylinder that is not combusting as it otherwise should.

This misfire is often most pronounced at idle, when engine RPMs are at their lowest, and each individual combustion event is most defined.

On the contrary, when operating at higher engine speeds, a single cylinder misfire is often easily overlooked. This is especially true of engines that utilize an eight-cylinder configuration, in which one dead cylinder leads to a lesser drop in overall contribution percentage than it would in an engine of a four-cylinder configuration.

How to Fix

The following steps can be used to assist you in diagnosing and repairing your vehicle’s noticeable shake at idle. As always, be sure to consult factory-specific service literature for your particular vehicle before attempting any such repairs.

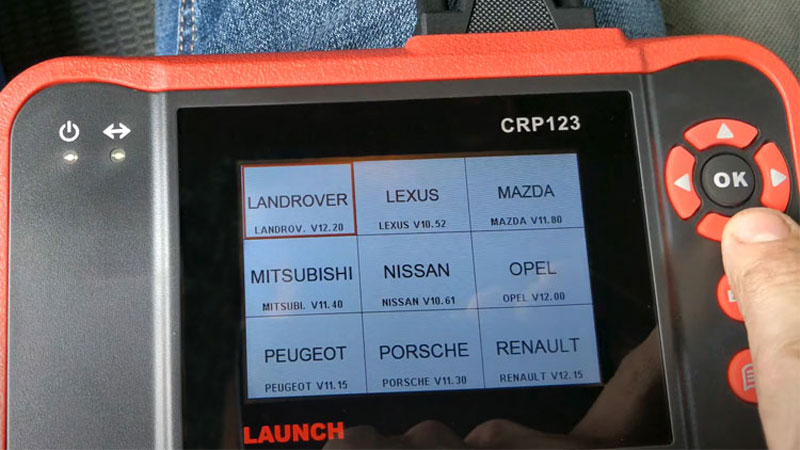

Check For DTCs

It is always a good idea to begin the diagnostic process by checking for any active or inactive fault codes using your OBD2 scanner (or having a local auto parts store scan it for you).

These codes often point a motorist in the general direction of the fault at hand. Any active faults should be thoroughly diagnosed before proceeding.

Inspect Air Filter

It’s important to check the condition of your vehicle’s air filter early in the diagnostic process, to avoid the potential of misdiagnosis. If your air filter appears overly dirty or soiled, it should be replaced immediately.

Check Ignition System Health

This is a particularly good time to check for proper delivery of spark to each cylinder. This can be easily done on standard ignition systems that feature individual plug wires for each cylinder, using nothing more than an inline spark tester.

Coil-on-plug ignition systems generally require each spark plug to be pulled and manually grounded for testing, in the absence of special test equipment. The spark plug gap/condition can also be checked at this time.

Test Fuel Pressure/Injector Operation

Next, you should validate the integrity of their vehicle’s fuel system. This can be done rather quickly with the use of a basic pressure gauge with the necessary attachments/fittings, and a bidirectional scan tool.

With your vehicle’s key in the “on” position, read the engine’s fuel rail pressure, and compare this figure to that specified by the vehicle’s manufacturer.

Following this, cycle each fuel injector using your scan tool, while watching for a slight momentary drop in gauged pressure. Any fuel injector that does not produce this anticipated pressure drop when cycled is suspect.

Evaluate Feedback From O2 Sensors

Using a quality scan tool, evaluate the feedback from your vehicle’s O2 sensors. Carefully check for any data that appears skewed, indicating the potential of a faulty sensor.

If all appears standard, compare these values to those specified by your vehicle’s manufacturer, checking carefully for an underlying lean condition that could be indicative of a vacuum leak.

Test For Vacuum Leak

Vacuum leaks can be tested for in a number of ways, the most accurate of which utilizes a purpose-built smoke machine.

If a smoke machine is not available, one can wand all vacuum hoses with an open, yet unlit propane torch, while listening for a sudden uptick in engine RPM. Any such vacuum leaks should be repaired before proceeding.

Inspect Idle Air Control Valve

If no issues have been uncovered to this point, there is a good chance that your vehicle’s idle air control valve is to blame. If possible, this valve should be removed, and cleaned to eliminate as much carbon fouling as possible.

In some cases, this might not be possible, and replacement, therefore, will be required.

Preventive Measures and Maintenance

Luckily, there are a number of measures that can be taken, in a bid to prevent engine-related vibrations at idle.

In fact, the vast majority of vibration causing conditions above can be avoided in their entirety, with a little bit of periodic TLC. After all, it is far easier to keep mechanical issues at bay now, than it is to remedy the effects of several years worth of neglect.

- For example, fuel injector life can be prolonged by periodically running a quality fuel injection cleaner through your vehicle’s fuel system.

- Likewise, a vehicle’s ignition system can be maintained through period removal and inspection of an engine’s spark plugs. Any fouled, or otherwise damaged spark plugs should be discarded and replaced.

- Additionally, all filter elements utilized in vehicle operation should be replaced at their factory-specified service intervals, or before, if significantly soiled. This includes the replacement of a vehicle’s engine air, and fuel filters, all of which have direct bearing over the manner in which an engine runs.

- Vacuum hoses should also be periodically inspected, and replaced once dry-rotting becomes evident. This task is generally far easier to complete than attempting to locate a vacuum leak from scratch, especially when the majority of an engine’s vacuum hoses look rather suspect, at best.

- 6 Epic Car Museums in Germany That Every Car Enthusiast Needs to Visit - Jan 22, 2024

- How Long Is a Car? (Average Lengths By Size Class) - Jan 10, 2024

- 8 Types of Tire Damage (Is It Harmless or a Huge Red Flag?) - Jan 1, 2024